Categories

New products

-

Lens Ring Joint Gasket

Equipped with Lens Ring Joint Gasket material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best Lens Ring Joint Gasket manufacturers and suppliers in China, you can buy our Lens Ring Joint Gasket in stock and check the price with our factory.

-

Double Jacket Gasket

Equipped with Double Jacket Gasket material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best Double Jacket Gasket manufacturers and suppliers in China, you can buy our Double Jacket Gasket in stock and check the price with our factory.

-

Corrugated Gaskets

Equipped with Corrugated Gaskets material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best Corrugated Gaskets manufacturers and suppliers in China, you can buy our Corrugated Gaskets in stock and check the price with our factory.

-

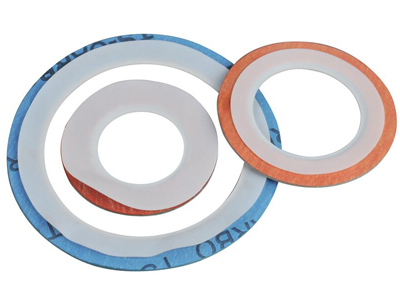

PTFE Envelope Gasket

Equipped with PTFE Envelope Gasket material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best PTFE Envelope Gasket manufacturers and suppliers in China, you can buy our PTFE Envelope Gasket in stock and check the price with our factory.

-

Rubber Sheet

Equipped with Rubber Sheet material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best Rubber Sheet manufacturers and suppliers in China, you can buy our Rubber Sheet in stock and check the price with our factory.

Constant seating stress gaskets

HIT:9 DATE:2015/3/25

The constant seating stress gasket consists of two components; a solid carrier ring of a suitable material, such as stainless steel, and two sealing elements of some compressible material installed within two opposing channels, one channel on either side of the carrier ring. The sealing elements are typically made from a material (expanded graphite, expanded polytetraflouroethylene (PTFE), vermiculite, etc.) suitable to the process fluid and application. Constant seating stress gaskets derive their name from the fact that the carrier ring profile takes flange rotation (deflection under bolt preload) into consideration. With all other conventional gaskets, as the flange fasteners are tightened, the flange deflects radially under load, resulting in the greatest gasket compression, and highest gasket stress, at the outer gasket edge.

Since the carrier ring used in constant seating stress gaskets take this deflection into account when creating the carrier ring for a given flange size, pressure class, and material, the carrier ring profile can be adjusted to enable the gasket seating stress to be radially uniform across the entire sealing area. Further, because the sealing elements are fully confined by the flange faces in opposing channels on the carrier ring, any in-service compressive forces acting on the gasket are transmitted through the carrier ring and avoid any further compression of the sealing elements, thus maintaining a 'constant' gasket seating stress while in-service. Thus, the gasket is immune to common gasket failure modes that include creep relaxation, high system vibration, or system thermal cycles. The fundamental concept underlying the improved sealability for constant seating stress gaskets are that

(i) if the flange sealing surfaces are capable of attaining a seal,

(ii) the sealing elements are compatible with the process fluid and application, and

(iii) the sufficient gasket seating stress is achieved on installation necessary to affect a seal, then the possibility of the gasket