Categories

New products

-

Lens Ring Joint Gasket

Equipped with Lens Ring Joint Gasket material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best Lens Ring Joint Gasket manufacturers and suppliers in China, you can buy our Lens Ring Joint Gasket in stock and check the price with our factory.

-

Double Jacket Gasket

Equipped with Double Jacket Gasket material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best Double Jacket Gasket manufacturers and suppliers in China, you can buy our Double Jacket Gasket in stock and check the price with our factory.

-

Corrugated Gaskets

Equipped with Corrugated Gaskets material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best Corrugated Gaskets manufacturers and suppliers in China, you can buy our Corrugated Gaskets in stock and check the price with our factory.

-

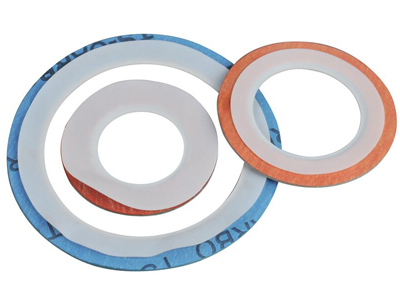

PTFE Envelope Gasket

Equipped with PTFE Envelope Gasket material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best PTFE Envelope Gasket manufacturers and suppliers in China, you can buy our PTFE Envelope Gasket in stock and check the price with our factory.

-

Rubber Sheet

Equipped with Rubber Sheet material and properties, Ningbo Kaxite Sealing Materials Co.,Ltd is one of the best Rubber Sheet manufacturers and suppliers in China, you can buy our Rubber Sheet in stock and check the price with our factory.

Non-Asbestos Jointing Sheets KNXB350

Non-Asbestos Jointing Sheets are made of special non-asbestos heat-resisting Fibre, heat-resisting packing material, and special rubber compound heating and compression molding it.

|

|

KNXB200 Non-Asbestos Jointing Sheets |

|

KNXB300 Non-Asbestos Jointing Sheets |

|

|

KNXB350 Non-Asbestos Jointing Sheets |

|

KNNY150 Non-Asbestos Jointing Sheets |

|

|

KNNY250 Non-Asbestos Jointing Sheets |

|

KNNY300 Non-Asbestos Jointing Sheets |

|

|

KNNY350 Non-Asbestos Jointing Sheets | ||

|

Non-Asbestos Jointing Sheets are made of special non-asbestos heat-resisting Fibre, heat-resisting packing material, and special rubber compound heating and compression molding it. |

|||

|

|

|

Material: Made of special non-asbestos heat-resisting Fibre, heat-resisting packing material and nature rubber compound heating and compression molding it. |

|

Item |

KNXB200 |

KNXB300 |

KNXB350 |

KNNY150 |

KNNY250 |

KNNY300 |

KNNY350 |

|

Tensile strength MPa |

5.0 |

7.0 |

11.0 |

8.0 |

10.0 |

12.0 |

15.0 |

|

Aging Coefficient |

0.9 |

||||||

|

Density g/cm³ |

1.6 - 2.0 |

1.6 - 1.8 |

|||||

|

Compressibility % |

12 |

||||||

|

Rebound degree |

35 |

40 |

45 |

40 |

45 |

50 |

50 |

|

Pliability |

No Crack |

||||||

|

Stress-relaxation |

45 |

45 |

45 |

40 |

40 |

30 |

30 |

|

Oil sealing |

|

|

|

10 MPa pressure for 30 min |

12 MPa pressure for 30 min |

15MPa pressure for 30 min |

16 MPa pressure for 30 min |

|

With the temperature of 150 |

Tensile strength-reducing % |

40 |

30 |

25 |

25 |

||

|

Thickness-increasing % |

5-20 |

5-20 |

5-18 |

5-18 |

|||

|

Appearance change |

No bubble |

||||||

|

With the temperature |

Tensile strength MPa |

5 |

6 |

8 |

10 |

||

|

Thickness-increasing % |

5-25 |

5-25 |

5-20 |

5-20 |

|||

|

Pliability |

No Crack |

||||||